Originally developed for the Nuclear industry for the evaluation of inspection approaches for complex challenges, reducing overall cost of validations and procedure qualification.

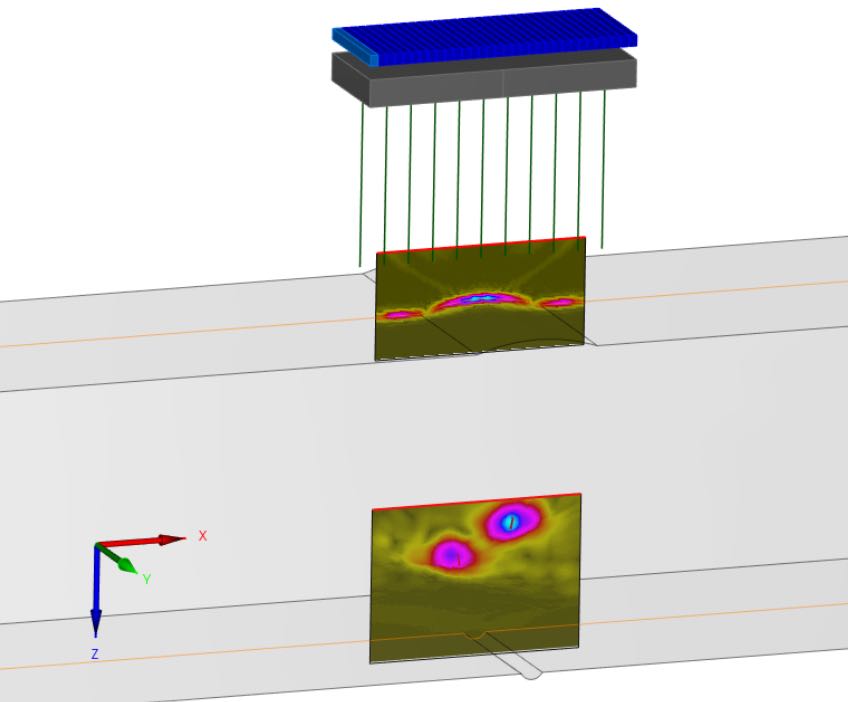

CIVA Modelling reduces the requirement for costly mock ups, establishing Probability of Detection (PoD) for any given flaw sizes against selected techniques and provides in depth knowledge of beam propagation against different grain structures within the test material and expected ultrasonic responses from flaws at different tilt and skew angles. The software platform has gained acceptance within the O&G sector for business-critical challenges which typically cover complex geometries where beam paths/profiles would be difficult to assess. A range of ultrasonic inspection approaches can be modelled, (UT, TOFD, PA and AUT) CIVA Modelling reduces the time required for on-site testing and increases the reliability of the tests.

Applications modelling can be used for the following;

-

Prediction and visualisation of ultrasonic fields

-

Prediction of the interaction of ultrasound with flaws of various types of geometry and orientation

-

Verification of the behaviour and enhanced imagery of ultrasonic beam propagation in components of complex geometry (e.g. pressure vessel nozzles)

-

Removal of expensive and timely validation activities

-

Enhanced imagery to assist with the understanding of ultrasonic beam propagation